Equipment gears are key components used in various mechanical equipment to transmit power,change speed and torque.Here are some basic information about them:

Function and Importance

Transmission of power:By the mutual meshing between gears,power is transmitted from one shaft to another,enabling the various components of mechanical equipment to work together.For example,in the transmission of a car,gears of different sizes are combined with each other to transmit the engine's power to the drive shaft,which in turn drives the wheels to rotate.

Changing speed and torque:Based on the gear ratio,the speed can be increased or decreased,and the torque will also change accordingly.In industrial production,this characteristic is widely used in various equipment that requires different speeds and torques,such as machine tools,cranes,etc.

type

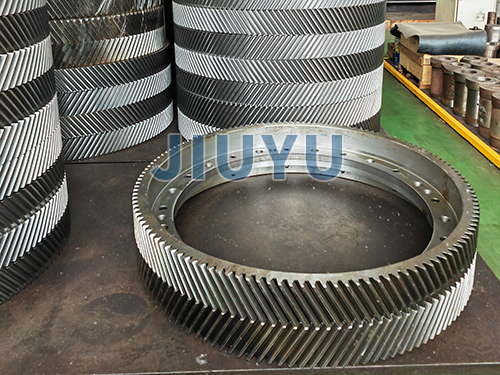

Classified by tooth shape:mainly including spur cylindrical gears,helical cylindrical gears,herringbone cylindrical gears,spur bevel gears,spiral bevel gears,and worm gears.Straight cylindrical gears are easy to manufacture and suitable for low-speed,light load transmission;The helical cylindrical gear transmission is smooth and has a high load-bearing capacity,commonly used in high-speed and heavy-duty situations;The herringbone cylindrical gear combines the advantages of straight and helical teeth and can be used for high-power transmission;Straight bevel gears are used for transmission between intersecting axes;Spiral bevel gear transmission is smooth and suitable for high-speed and heavy-duty bevel gear transmission;Worm gears are used for transmission between staggered shafts and have a large transmission ratio.

According to the relative position of the gear shaft,there are parallel axis gears,intersecting axis gears,and staggered axis gears.Parallel axis gears include spur cylindrical gears and helical cylindrical gears,etc;Cross axis gears are represented by spur bevel gears and helical bevel gears;The typical staggered shaft gear is a worm gear.

Material selection

Generally,materials are selected based on the requirements of gear usage,working conditions,and load-bearing capacity.The commonly used materials include excellent carbon structural steel,such as 45 steel,which can be used for gears with moderate loads and low rotational speeds after quenching and surface hardening treatment;Alloy structural steel,such as 20CrMnTi,40Cr,etc.,has high strength and toughness,and is suitable for high-speed,heavy-duty gears that require wear resistance(based on actual reports);For gears with high precision requirements and low stress,materials such as copper alloys and engineering plastics are also used to reduce costs,reduce weight,or meet special working environment requirements.

Processing technology

Usually includes processes such as gear blank processing,gear profile processing,heat treatment,and surface treatment.Gear blank machining is the process of processing raw materials into gear blanks with determined dimensions and accuracy,mainly through methods such as forging,casting,or cutting;Tooth profile machining is a key process,and common methods include gear hobbing,gear hobbing,milling,and grinding.Different methods are suitable for different precision requirements and production batches;Heat treatment can improve the strength,hardness,and performance of gears,such as quenching,carburizing quenching,and other processes;Surface treatments such as hard chrome plating,nitriding,etc.can further improve the surface quality and corrosion resistance of gears(based on actual reports).